|

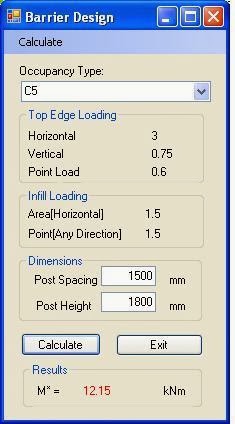

| vb.net application screenshot |

However in the process I removed two features:

- Wind loading on barriers

- The ability to limit top edge loading height

|

| MS Excel version |

If people are pushing up against a barrier which could either be a solid infill panel such as glazing or closely spaced rails, then loading is going to be more concentrated area load somewhere between shoulder height and hip height. Anything above the shoulders and below the hips is more like a wall of light weight construction than a barrier. Though at heights below the hips of an adult a barrier may be subject to loading from children: and impact loading may be more important than static loads. Any case the basic idea adopted is that the top edge loading is a line load which either applies to a guard rail or a panel, but at a height no greater than 1100mm (above floor level). If necessary a separate guard rail can be placed in front of glazing or other panel. Which is another issue: not every location where a so called balustrade is placed requires a hand rail. Hand rails and guard rails are not one and the same thing, and further more the maximum and minimum heights for handrails and guardrails are different. If handrail and guardrail are one and the same element, then the typical install height is 1000mm to meet the height requirements of both functions.

|

| Wind loading on barrier |

As wind loading is seldom an issue, it can be considered separately as a check to ensure that isn't an issue, for this purpose I created a separate spreadsheet. To keep it simple, it takes the site ultimate strength reference pressure (qzu) as an input parameter. Once again this can be determined from a separate spreadsheet if not known. For example over at ExcelCalcs I have the following spreadsheets:

- AS4055v2

- schWindAssessment to AS1170.2

However given that my wind load calculations are based on vba functions it does require schTechLIB. Since people have problems using my spreadsheets based on the schTechLIB add-in, its another reason for excluding the wind loading. I have no intention of ever doing the wind loading calculations directly in the worksheet: there are too many conditionals and the cell formula would be unreadable and prone to difficult to trace errors: I therefore prefer vba functions to cell formula.

Note that in calculating the base moment for the wind loading, the panel load is distributed to the full height of the post. Further refinement of the calculations would be required to place a partial uniformly distributed load within the span of the cantilever. It also ignores eccentricity for the wind load, this is considered only significant if dealing with a single isolated panel. So some modification would be required if wished to use for calculating base moment for say an advertising sign.

|

| Two windows on same workbook but different worksheets |

As indicated the original spreadsheet had vba formula for design of the balustrade. This vba code was written to iterate through various parameters and find limits relating loads, rails spans and post heights, and otherwise generate selection tables. The problem with spreadsheets presenting some form of readable report, reflecting paper base calculation, is that have to move up and down through the report to modify parameters. Simpler tools are required for quick calculations. When I build a spreadsheet I try to get all design parameters together on a single worksheet or otherwise grouped together across several worksheets, but otherwise separated from the report. With this approach I can at least open two windows of the same workbook, with one looking at the report and the other at the result I need. Still such approach is not as compact as it could be, or as quick at getting to the result really need: uses too much screen real estate. Also vba code, or code in any other high level language is easier to transform into alternative calculations: from checking a single barrier to generating tables and design curves. Whilst extra features are typically easy to add to a spreadsheet: often adding a feature can be cumbersome using worksheet calculations.

Still barrier calculations for a cantilever post can be relatively simple, if ignore some of the complications. The following screen shots show the progression of the workbook. Starting with simply calculating the base moment, then adding automatic selection of suitable post section from table of capacities.

|

| Stage 2: calculate base moment |

|

| Stage 3: Look up suitable section in capacity table |

|

| User selectable post section |

|

| User Selectable section plus recommended minimum section |

Having done that then may be useful to add in the issue of limiting top edge load height and also wind loading.

|

| With Wind loading and Top Edge Height Limit |

As wind loading is seldom the critical loading, I added modifications to return the description of critical load case and also to provide moment due to wind load. As with the wind loads on barrier spreadsheet, the value of the site reference pressure qzu is a required input rather than calculated by the workbook. This keeps the input parameters to a minimum. If qzu is zero, then base moment due to wind loading is zero and doesn't affect the main results. Also added some conditional formatting highlighting the 3kN/m crowd loading, and also turning resistance of selected section green when greater than design moment.

|

| Screen scrolled to see wind loading |

The spreadsheets can be downloaded via the following links:

- wbk2dsgnBarrierPost.xls

- wbk3dsgnBarrierPost.xls

- wbk4dsgnBarrierPost.xls

- wbk5dsgnBarrierPost.xls

- wbk6dsgnBarrierPost.xls

- windBarrierPost.xls

- schTechLIBV2.xla {alternative schTechLIB with DAO reference removed}

If manufacturers have the capacities or resistances of their posts and the post connection components then these can be easily added to the workbook. Also the steel sections included are not there specifically as suitable for barrier posts, but also for additional simple checks for support structure. If a barrier post is connected in a suitable manner then it will transfer its base moment to the support structure in bending. Attachment to a fascia beam however will typically result in base moment being transferred via torsion in the fascia, and cannot be checked. Also spreadsheet is currently only checking capacity about strong axis of section: basically the axis which would typically choose. Another complication not covered is biaxial bending of corner posts. Cable barriers are a situation which would also produce biaxial bending of all posts, due to forces in the plane of the barrier as well as normal to the barrier.

In short barriers can range from the simple to the complicated, and therefore there is lots of scope to further extend this little workbook. However increasing flexibility of something can make it less useful and more prone to incorrect use with incorrect settings. So its better to have custom workbooks or applications to suit the specific purpose, with out having complications of features not interested in.

These spreadsheets can be further extended by adding printed report of the calculations, a simple summary or specification sheet, and possibly certificates of adequacy. All depending on additional needs.

Revisions:

[24/04/2014] Original

[23/04/2016] Changed download links to MiScion Pty Ltd Web Store